Bioproduct Innovations to Increase Farmer Profitability

By Courtney Heiser

The Ohio Soybean Council and soybean checkoff fund many different research projects that utilize soybeans, thus increasing demand for soybeans and helping farmers become more profitable. OSC continually works to explore new, innovative market outlets for soybeans and their by-products. Below are some of the latest research ventures that aim to increase market value for soy growers.

Torrified Hulls

Torrified hulls to replace carbon black is a compounding filler produced from a soy hull that seeks to reduce carbon black usage in U.S. tires. Not only is it a more environmentally-friendly product, reducing energy consumption and pollution from carbon black production, but it is also a higher quality product that is providing another market outlet for surplus soybeans.

There are enough raw materials to replace nearly all carbon black tires in the U.S. Torrified hulls could replace the 5 million annual tons of carbon black at about $2,400 per ton. The product is also proven to significantly reduce the weight of rubber composites and result in less waste and is the result of a simple, green biological process.

OSC is currently testing and researching this product. So far, they have produced a soy filler, produced and improved preliminary rubber composites and continue to examine enzyme destruction of soy hulls to enable a better design process. From here, OSC plans to improve and increase filler production, study filler performance, and partner with a filler producer to eventually get our product on the market.

Functionalized Hulls

As water quality continues to be a top priority for Ohio agriculture, functionalized hulls to absorb phosphorous is a desirable new technology. This compostable and recyclable product aims to reduce phosphorus losses from agricultural soils that impair surface water quality. Modified soy-based hulls trap reactive phosphorus while reducing sediment loss. In testing, the material reduced leachate reactive phosphorus by 87 percent, surface runoff by 70 percent, and total average sediment loss by 60 percent. This product continues to be tested and researched further, but there are hopes to partner with a company to get this product branded and commercially available soon.

Soy Vodka

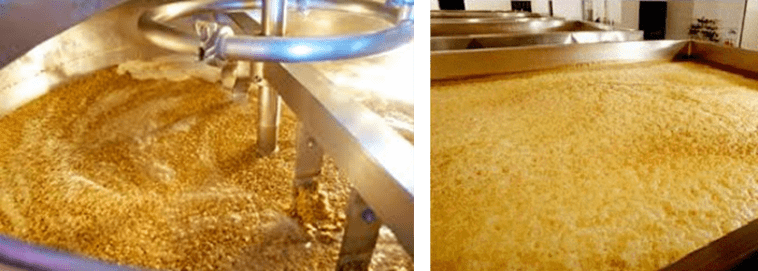

Currently, there are no other U.S. producers or marketers of vodka made out of soybeans. But soon, through a project funded by Ohio checkoff dollars, one could exist. Soy vodka could share 1 percent of the vodka market which is equivalent to revenues of over $5 million. Research is still being conducted on this project, but there are hopes for a commercial company collaboration soon.

Although these projects are not yet commercially available, the Ohio Soybean Council continues to research and improve each project to stay a leader in advancing technologies to provide additional market outlets for soy growers.