Connecting Ohio Soybeans to the World, Enhancing Farmer Competitiveness

By Mike Steenhoek, Executive Director, Soy Transportation Coalition

As Ohio and U.S. soybeans remain under pressure due to uncooperative weather and growing conditions, on the supply side of the equation, and international marketing challenges, on the demand side of the equation, it becomes all the more essential to ensure our nation’s multi-modal transportation — the connection between supply and demand — is emphasized and prioritized. Unfavorable growing conditions is often a function of the weather. International marketing stress is largely a function of geopolitical acrimony. However, the challenges confronting our transportation system is largely due to a lack of understanding and will. Farmers can do something about that.

“Bottom line — transportation is a cost of doing business,” says Todd Hesterman, a soybean farmer from Napoleon, Ohio, and board member on the Ohio Soybean Council and Soy Transportation Coalition. “If we can have a system of roads and bridges, highways and interstates, inland waterways, freight rail, and ports that is more and more efficient, that will result in subtracting cents from the final per bushel delivered price. Transportation must continue to be a focus of farmers. Our competitiveness depends upon it.”

The Ohio Soybean Council is one of the founding member organizations of the Soy Transportation Coalition (STC) — comprised of 13 state soybean boards, the American Soybean Association, and the United Soybean Board. Given how the soybean industry, and much of agriculture, has a diverse and elongated supply chain, it is necessary to be actively engaged in each of the major modes of transportation of consequence to farmers.

Deepening the Lower Mississippi River: Soybeans’ Number One Launching Point

The 256-mile stretch of the Mississippi River from Baton Rouge, Louisiana, to the Gulf of Mexico accounts for 60 percent of U.S. soybean exports, along with 59 percent of corn exports — by far the leading export region for both commodities. There is a growing effort among Mississippi River stakeholders, including agriculture, to promote the dredging of the lower river shipping channel from 45 ft . to 50 ft . in depth.

According to research funded by the STC, the shipping costs for soybeans from Mississippi Gulf export terminals would decline 13 cents per bushel ($5 per metric ton) if the lower Mississippi River is dredged to 50 ft . A deeper river will allow both larger ships to be utilized and current ships being utilized to be loaded with more revenue-producing freight.

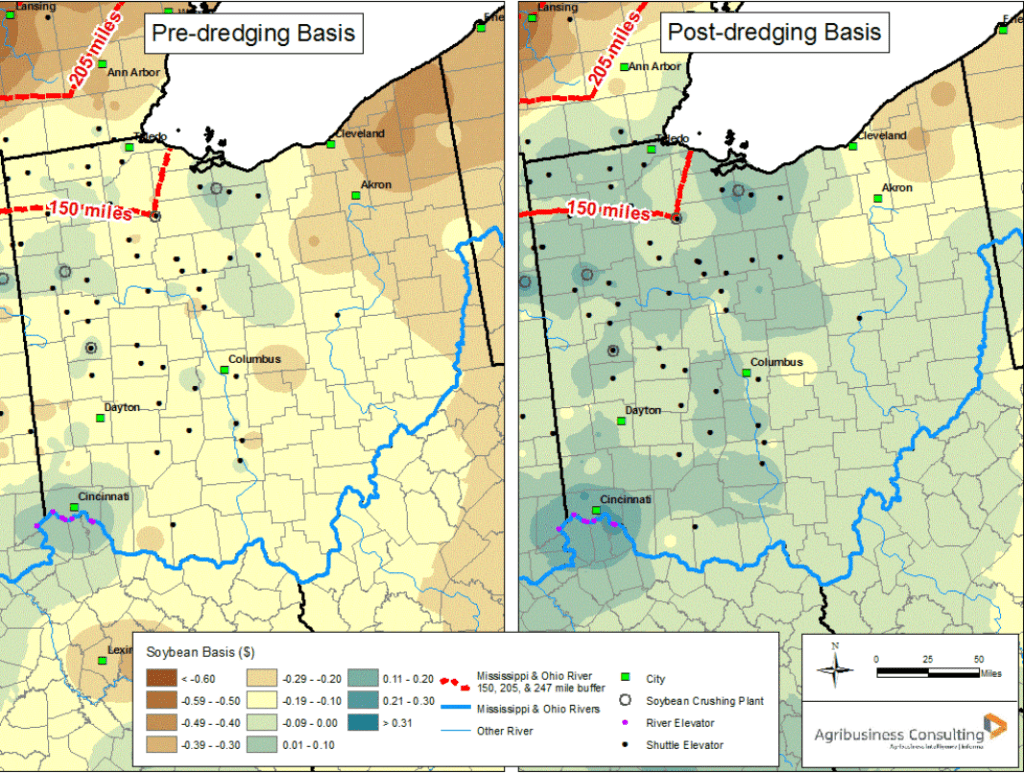

The research also highlights the impact on interior basis — the difference between the local price a farmer receives and the market value established by the Chicago Board of Trade — for soybeans in 31 states if the lower Mississippi River shipping channel is dredged. It is well established that farmers located in closer proximity to the nation’s inland waterways and barge transportation enjoy a positive or less negative basis vs. soybeans grown in areas further removed. As a rule, the less-costly and more efficient the supply chain is subsequent to farmers delivering their soybeans, the higher value a farmer will receive for the bushels of soybeans produced. The STC directed the researchers to produce basis maps for soybean-producing states located adjacent to navigable inland waterways — highlighting the current situation and how basis could improve for soybean farmers if the lower Mississippi River shipping channel is dredged to 50 ft.

Safer, More Efficient Truck Transportation

Recent analysis by the STC examined the impact of increasing semi weight limits on the interstate system on: 1.) Motorist safety; 2.) Infrastructure wear and tear; 3.) Carbon emissions and fuel consumption; and 4.) Potential cost savings and efficiency gains for agriculture and the U.S. economy.

The research highlights that adding an additional sixth axle to a semi weighing 91,000 lbs. will not only create additional braking capacity but will also produce greater vehicle handling and stability compared to the standard five axle, 80,000 lbs. truck. Moreover, allowing six axle, 91,000 lbs. semis will result in fewer semis on the road compared to maintaining an 80,000 lbs. weight limit, which will result in fewer motorist accidents and injuries. Research validates that motorist safety is strongly a function of the number of semis over a given stretch of road. Allowing six axle, 91,000 lbs. semis will result in a decrease in truck density — resulting in an increase in motorist safety.

A six axle, 91,000 lbs. semi will result in a reduction of weight per tire compared to a five axle, 80,000 lbs. semi — reducing wear and tear on the nation’s roads. In addition, a six axle, 91,000 lbs. configuration is compliant with the Federal Highway Administration’s Federal Bridge Formula — meaning that such trucks will meet weight distribution requirements for bridges on the Interstate Highway System.

For transporting soybeans and soy products, allowing six axle, 91,000 lbs. semis will result in fewer truck trips, fewer gallons of fuel consumed, fewer tons of carbon dioxide emissions, and reduced fuel costs. The use of a six axle, 91,000 lbs. semi will enable a farmer to transport an additional 130 bushels of soybeans per load.

Rural Bridges: The First Link in the Supply Chain

For a number of years, the STC has been promoting the use of load testing equipment when evaluating rural bridges. By doing so, bridges receive a more data-based, objective assessment and the results are: 1.) Bridges receive a more precise rating, and 2.) Counties and other local governments are able to allocate scarce resources to those bridges that are most acutely in need of repair.

The STC recently completed a successful collaboration in Midland County, Michigan. The total upfront cost of the project was $22,000. The Soy Transportation Coalition provided $10,000 to help underwrite the cost so the total initial cost to Midland County was $12,000. Midland County now owns the sensor kit (the STC has no ownership). The county engineer and his team have thus far tested four posted bridges. After the testing, the postings on all four were removed. They are now proceeding with testing additional bridges. It will continue to be utilized within the county. Since the project was so successful, a second Michigan county has proceeded with a similar project. Similar agreements for load testing have occurred with a county in southwest Kentucky and another project in southeast Kansas so momentum continues. The STC has $10,000 available to help underwrite the cost of a similar bridge load testing project in Ohio similar to what we have done/are doing with a number of counties.

“There is often a significant distance between where Ohio soybeans are grown and where they are consumed,” says Scott Metzger, a soybean farmer from Williamsport, Ohio, and board member on the Ohio Soybean Council, the Ohio Soybean Association, the American Soybean Association and the Soy Transportation Coalition. “Therefore, having an efficient transportation system can be a major factor in farmer profitability. Whether it’s roads, bridges, railways, locks and dams, or ports, the Soy Transportation Coalition is actively engaged to ensure our transportation system better positions soybean farmers for success.”